Technical fabrics

with impact absorption

The Tibeka Protections technology enters in the conception of high performance protection products

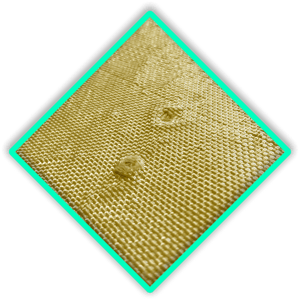

A DEEP INNOVATION OF THE TECHNICAL FABRIC

The innovation of this fabric, rests on an arrangement and a specific architecture of high performance fibers conferring to the fabric technical and mechanical properties until then incompatible.

UP TO 93%

OF ABSORBED ENERGY

+

A PERFECT

FORMABILITY

A COMPLETE PROTECTION FOR SEVERAL RISKS

PERFORATION

Les tests sont en cours de passation, nous indiquerons très prochainement les résultats.

TEARING

The tests are in progress, we will indicate the results very soon.

DEFORMATION

The tests are in progress, we will indicate the results very soon.

PULLOUT

The tests are in progress, we will indicate the results very soon.

ABRASION

The tests are in progress, we will indicate the results very soon.

MARKETS WHERE OUR TECHNOLOGY IS PARTICULARLY EFFECTIVE

-

Defense / balistique

-

Sports Protections

-

Professional protective equipment

-

Aerospace

To adjust a protection level NIJ IIIA to the standards 1010.06 to any shape

- Women's body armor that can be adjusted to the morphology of each woman.

- Technical luggage

- Ballistic canvas for base camps

- Protective covers for vehicles or gabions

The alternative to plastic with a perfect fit.

- Shin guards

- Knee pads / elbow pads for sliding sports

- Fencing breastplate

- Fencing bustier

For multi-protection without compromising its ease and precision

- Protective or motorcycle jackets

- Anti-shock and anti-cutting protection gloves

- Work pants

- Protective shoes

To protect against high velocity impacts while maintaining the flexibility of a fabric

- protective canvas for homes or shelters

- space suits

- shielding and protection of materials

THEIR TRUST IS ESSENTIAL TO US

Tibeka Protections is currently hosted in the incubator Un Cube Axel of the Euramaterials site of excellence and benefits from the label "High Potential Project" delivered by the Hauts-de-France Region through its Hauts-de-France Innovation Development (HDFID) cell. Our fabric has been developed in collaboration with the textile research laboratory GEMTEX of ENSAIT and its industrialization is facilitated by the textile business club CLUBTEX.

MASTERED AND SECURED KNOW-HOW

From its conception to its integration, Tibeka Protections controls the whole production process. Thus, thanks to our skills, our tools or our network, we will know how to create or adapt our fabric to your specifications.

DESIGN

Looking for resistance, flexibility, deformation, lightness ... does your request require an adaptation of our technical fabric? Our innovation team will help you to determine the feasibility of your project.

WEAVING

The manufacture of the technical fabric or its declinations is carried out with the help of an innovative 3D weaving, carried out in trusted partners licensed and soon within our production plant.

ASSEMBLY

From 1 to 8 layers, we can superimpose our fabric in order to give it the technical and/or mechanical specificities required.

CUTTING & FORMING

We cut and formed the fabric according to the desired pattern and/or volume.

TREATMENTS

UV resistance, liquid permeability, shape retention... Our fabric can be treated or coated according to your specifications.